SAPONIFICATION PROCESS - Saponification Plant

Main menu:

SAPONIFICATION PROCESS

JET SAPONIFICATION PLANT

The JET Saponification Plant requires a minimum steam consumption of about 100 kg/h each 1,000 kg/h of produced soap. The maintenance is simple and minimum. The JET has no moving mechanical parts; the pumps are the only moving parts of the process. The process is atmospheric. The plant is user-friendly and is easily controlled by a single operator. Easy visual access to all process points.

In the Full-Boiled processes the process water is abundantly used and remains into the soap. A typical concentration of full-boiled neat soap is 62% TFM and 33% water. A Semi-Boiled soap obtained with a conventional plant has a typical concentration of 58% TFM (glycerine excluded) and 30% water. The high content of water is necessary to facilitate the saponification and obtain a homogeneous soap mass. The JET Semi-Boiled saponification allows the production of neat soap at a very wide range of concentrations. It is possible to produce soap at 58% TFM as with a conventional plant and it is possible to produce:

- SEMI-CONCENTRATED SOAP – With a water content in the range of 20%, the soap can be just cooled down, without any evaporation, in order to obtain Laundry Soap or it can be processed by a Drying Plant with reduced Heat Exchanger and reduced Vacuum Section in order to evaporate a limited quantity of moisture and obtain Semi-boiled Toilet Soap.

- CONCENTRATED SOAP – With a water content from 16% down to 12% there is no further scope of drying and the soap is to be cooled down in order to obtain Semi-boiled Toilet Soap. A compact Chill-Roll plant is the ideal heat-exchanger to complete the process without the need of a more complex and consuming Drying Plant.

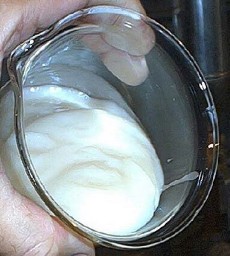

EMULSIFYING JET

Simultaneously to the supply of the reagents, the JET receives a small flow of steam of which, flow and pressure, can be fine-tuned for the formation of the best emulsion.

Steam Injection has several functions:

- Provides the necessary kinetic power to generate a great emulsionated interphase.

- Triggers the saponificaton reaction providing the required thermal energy.

- Immediately increases the relative electrolytes percentage so as to allow sudden generation of enough quantity of soap necessary to keep a stable emulsion, whatever the level of free fatty acids might be.

CONTINUOUS SAPONIFICATION REACTOR

The Reactor is a relatively simple vessel consisting of three stages:

- THE RECEIVING STAGE - Here the JET releases the emulsion. It is completed with a rotating screw which facilitates the passage of the reacting mass to the second stage.

- THE REACTION STAGE – Here the reaction completes its linear phase. On the bottom of this second stage a pump allows the recycle of the soap from the bottom to the top; the same pump is used to empty the two first stages when required. The soap overflows to the third stage.

- THE COMPLETITION STAGE - Here the soap matures for a complete saponification. On bottom of such stage a pump delivers the soap to the downstream equipment or, when required, recycles it.

Thanks to its flexible design the described reactor can be also used as a batch plant, in such case the delivery pump is set to the recycle mode until the operator decides to download the soap.

SAS MARIANI TOMMASO, VIA TOSCANINI 46, 20831 SEREGNO (MB) - ITALY

Phone: +39 0362-239988 - Fax: +39 0362-328413 - www.sasoap.com