GALLERY SOAP PLANT - Saponification Plant

Main menu:

GALLERY SOAP PLANT

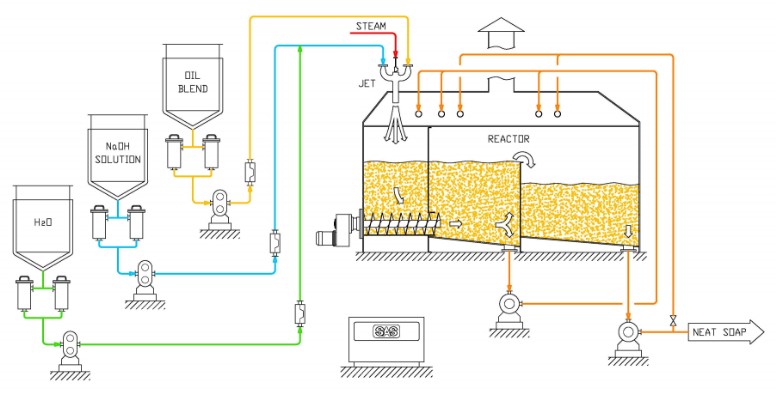

Saponification Reactor receiving oil blend, caustic soda and soap in form of foam emulsion from the JET. The first stage of the saponification reactor is connected to the second by a motorized screw for positive product flow to the second stage; second, third and fourth stages are partially separated by baffles to allow a continuous flow of the soap.

Raw materials are dosed in correct proportions through Filters to the JET and finally to the Continuous Saponification Reactor by the pumps. The saponification starts in the specially designed Emulsifying JET where the oil blend and the alkali immediately start reacting and generate an emulsion (oil-alkali-soap) discharged in a multi-stage Reactor at atmospheric pressure. Here the generated soap emulsion, in form of creamy foam, completes the saponification reaction by slowly flowing through the various stages. The final TFM content is determined by the concentration of caustic soda solution injected into the JET; this concentration can be finely tuned by adjusting the pumped quantity of water (or brine). The combination of the JET and the Soap Reactor allows the start of the saponification process even with high concentrations of caustic soda therefore it is possible to obtain a neat soap up 74% TFM (or 78% TFM using Fatty Acids instead of Oils) without need of any further drying process. The neat soap is then pumped by a special soap pump to Soap Chill Rolls (for concentrated soap) or to Vacuum Dryer (for standard neat soap).

SAS MARIANI TOMMASO, VIA TOSCANINI 46, 20831 SEREGNO (MB) - ITALY

Phone: +39 0362-239988 - Fax: +39 0362-328413 - www.sasoap.com