Soap Wrapping Machine - Soap Packaging Machine

SOAP WRAPPERS

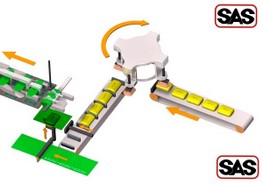

The WRAPPEX soap wrapping machines have been studied for medium/big soap finishing lines with maximum speed up to 180 soap wraps per minute. Our Wrappex soap wrappers are very flexible and can be easily understood by the operators so it is oriented to such applications where there is need of repeated change-overs and soap shapes might be quite different.

The Wrappex soap wrapping machines have new developments and takes advantage of the new technologies to make possible movements which in the past were obtained by complicated mechanical solutions. However they also keeps a major mechanical core for all the critical movements. The idea has been to design a soap wrapper which keeps all the goodies of the existing models, which is not too innovative in terms of wrapping process but which is even easier and quicker to be set up and for day-by-day use.

MODELS:

WRAPPEX/120: up to 120 wrapped soap bars per minuteWRAPPEX/150: up to 150 wrapped soap bars per minute

WRAPPEX/180: up to 180 wrapped soap bars per minute

WRAPPEX/L: for extremely large and thick soap bars

The WRAPPEX soap wrapping machine is supplied complete with:

• main electrical motor with electronic frequency inverter

• in-line infeed with rotary suction-cup group

• 2 infeed reel holders for outer paper

• 2 infeed reel holders for inner stiffener

• outer-wrap & carton stiffener infeed and “twodirections” registration system by servo-driven motor

• electronic cam positioner to control the phases of vacuum, etc.

• electronic controllers for the temperature of the sealing resistances

• BOPP kit for the use of polypropylene outer wrap

• switch to control the several safety covers

• electrical and electronic panel

• main electrical motor with electronic frequency inverter

• in-line infeed with rotary suction-cup group

• 2 infeed reel holders for outer paper

• 2 infeed reel holders for inner stiffener

• outer-wrap & carton stiffener infeed and “twodirections” registration system by servo-driven motor

• electronic cam positioner to control the phases of vacuum, etc.

• electronic controllers for the temperature of the sealing resistances

• BOPP kit for the use of polypropylene outer wrap

• switch to control the several safety covers

• electrical and electronic panel

Home Page - Soap Wrappers - Flow Pack - Pleat & Stretch - Accessories - Reconditioned - Contacts - Videos